4000 Controller

The Series 4000 Embedded Controller provides an unrivalled array of features to operate marking machines, manage unique product identifiers, such as serial numbers for asset tracking, and manage user access. The controller is for use with dot and scribe marking machines, portable, benchtop and production line integration models.

- Comes as standard with all dot marking and scribe marking equipment (except the P60-30 Touch)

- Available to purchase separately as an upgrade for most marking machines supplied with the previous generation controller

- Available as a battery powered unit for extra mobility and flexibility

- Panel mounted Integrations version is available for integrators

SKU: N/A

Category: Controller Options

- Video

- Features

- Configuration by machine

- Accessories

Video

Features

- Resistive, 10.4” touchscreen – usable with gloves

- Two axis control (X-Y marking directions), expandable to 4 Axis for Z and C axis control

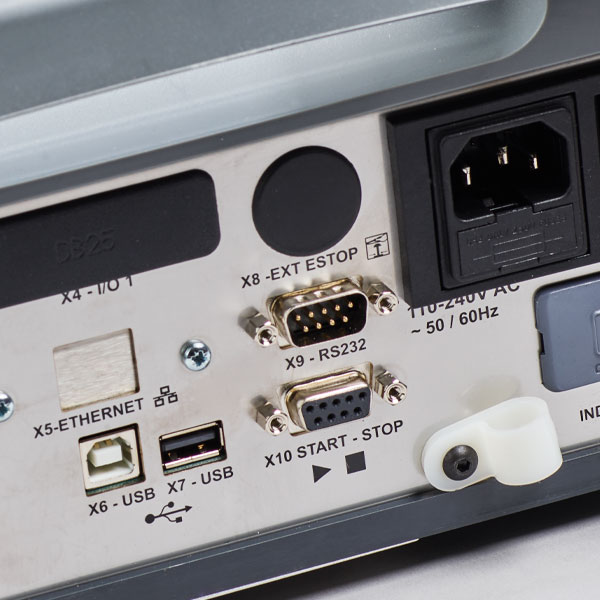

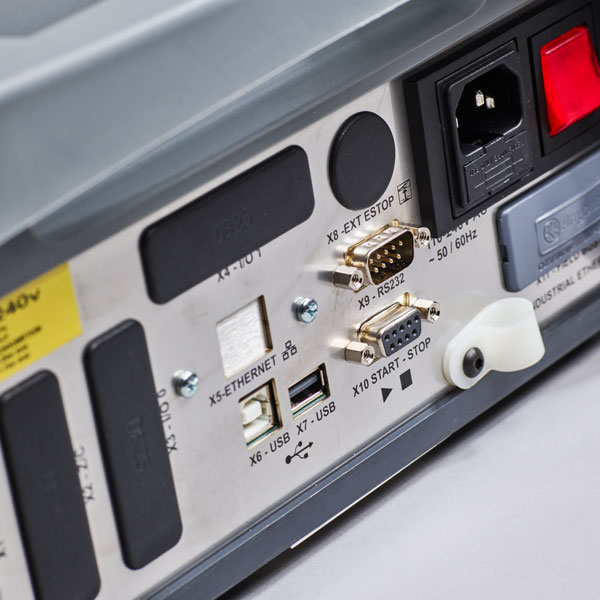

- USB type A, USB type B and RS232 ports, for connecting to optional USB drive, USB keyboard, PC and barcode scanners (RS232)

- Firmware updates via USB drive

- Integrated help animations for instant user training

- 110V or 230V mains power supply

- Password security for all menu items

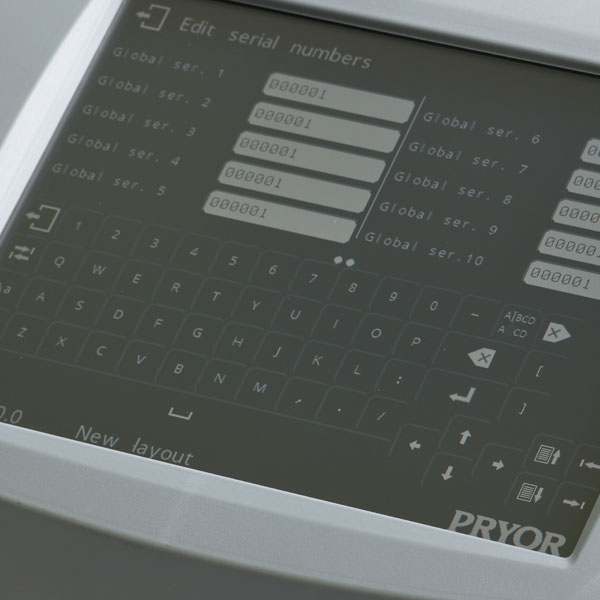

- Data logging to .csv file on USB stick or internal memory

- Duplicate check of last 100 marks within 1 of 5 different logs of marks

- Live view of layout during jogging / drag and drop repositioning of layout

- Built in emergency stop

Applications

- Control of all Dot Peen and Scribe marking machines – bench mounted, portable and integrations models

- Connection of marking machines to PC for use of windows-based software control

- Bench-top marking machines

- Portable marking machines

Logos

- Logos can be drawn directly on the controller touchscreen

- Pixel editor and simple line drawing tools as standard

- Logos can be imported from USB stick

- Saved logos now selectable from a menu list

- Saved logos now have on-screen preview

Customisable Operator Interface

- Bespoke graphics or visual instructions can be designed and implemented

- On-screen controls for system features

- Clear, graphical instructions

- Input options can be limited for simple operator instructions

- Customisable password protection

USB Memory Stick Interface

- Transfer individual layouts to/from the controller

- Complete layout and configuration backup and restore

- Firmware updates

- Data logging of all marks made to .csv file

- Mark data from an excel csv file. Lookup mode or sequential mode.

- Logo importing from files

On Screen Operator Instructions

Customisable operator instructions can be saved as part of a layout and shown on screen whenever that layout is to be marked.

Trial Run Screen

- Layout can simply be dragged around the screen to a new location

- Machine responds in real time to edits

- Corner to corner outline of mark allows easier checking if the machine is aligned at each extremity

- Incremental jogging of mark dimensions and orientation

Communication Options

- Ethernet TCP/IP (Socket communications)

- Profinet

- Profibus

- Ethernet/IP

- DeviceNet

- EtherCAT

- Integrates to SQL server

- Fully integrates to Pryor PC based software package for data logging, duplicate checking and data reporting

Password Protection

Various Password protection options.

- Each password can be applied to each menu option individually to restrict access

- User groups with different access levels

- Each user group can be given access to every menu option individually

- Users then have own passwords and are assigned to one of the user groups

- e.g. Admin has full control, Supervisors can edit settings and layouts, operators can only load and mark layouts

- Full integration to Pryor PC based software for database management of password controls and access levels

I/O Management

Improved I/O control screens

- Full view of all 32 input and 24 output status in 1 screen (if 4 I/O cards installed on integrator version)

- Detail view of each I/O card

- Screen showing indicators for status of each input / output

- On-screen toggling of each input

- Inputs / outputs can be named for easy identification

- Easy checking if data is being sent / received