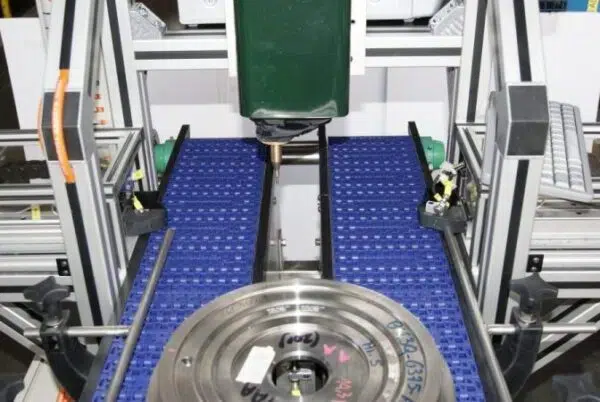

InDot Dot Peen Marking Machine

The Pryor InDot range of dot-peen marking machines provide a sequence of impact dot marks that create a human or machine readable inscriptions such as identification codes, logos and 2D Data Matrix barcodes. This range of machines is compact and designed to be integrated into either an existing production line, or integrated into a turnkey bespoke installation.

- Designed for integration into an existing production line, or into a turnkey bespoke installation

- Ideal for high volume production rates

- Often used in the aerospace industry due to unbeatable dot matrix dot accuracy

- Various marking window size options

- Various controller options

- Features

- Technical Data

- Accessories

Features

The InDot range of integratable dot peen marking machines is ideal for high volume output or for adding to existing production lines. They can be integrated into any industrial or commercial application, or they can be installed as part of turnkey bespoke solution. The compact nature of the machine and high marking area to machine size ratio makes them very easy to integrate. The standard machines are powered by electromagnetic solenoid and there is no need to connect air supply.

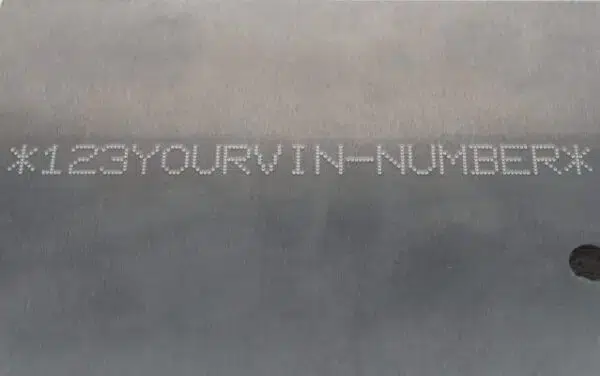

The marking heads are driven by a lead screw mechanism that ensures absolute dot precision which is vital in 2D Data Matrix code marking, extensively used in the aerospace industry. The force control is variable to enable the operator to program the machine for optimum output on the material that is being marked. This ensures accurate marking depth when adhering to critical standards. The flat X/Y linear movement of the marking head also ensures depth consistency.

The high speed of the integrated dot marking head is also controllable, allowing the user to tailor the speed of the marking to the exact cycle time requirements.

The InDot range of integrator marking machines provides a many various marking options, one of which is the marking window size. Pryor offers a large variety of marking window options, allowing the user to choose an optimal window for the amount and size of information they are planning to mark. The InDot range also provides a range of controller options: the 4000 controller, or the option to link to a PC via one of the two controllers using our Windows based software to drive the machine.

Technical Data

- Marking window sizes:

- 50mm x 25mm,

- 130mm x 30mm,

- 60mm x 60mm,

- 150mm x 150mm,

- 300mm x 150mm,

- Others available on request

- Standard Character Sizes: 0.15mm – 99.9mm in increments of 0.15mm

- Standard Marking Formats: 5 x 7, 7 x 9, Varidot, HPGL, BMP Logos

- Electrical Supply: 220v/110v

- Electromagnetic Solenoid with programmable depth settings. Capable of marking all engineering materials up to 62HRc (800Hv)

| Marking Window: | Dimensions: |

| 50mm x 25mm | 226mm (H) x 133mm (W) x 92mm (D) |

| 130mm x 30mm | 225mm (H) x 220mm (W) x 122mm (D) |

| 60mm x 60mm | 351mm (H) x 237mm (W) x 244mm (D) |

| 150mm x 150mm | 344mm (H) x 359mm (W) x 359mm (D) |

| 300mm x 150mm | 326mm (H) x 515mm (W) x 300mm (D) |

- 4000 Controller:

- Large 10.4 inch full colour screen

- Resistive screen is usable with gloves

- Integrated help animations demonstrate common functions

- Impact resistant screen

- Preview of layout on main menu screen

- Detailed preview improved with variable dot size, grid, auto zoom

- USB keyboard can be connected if preferred

- Find out more about 4000 Controller here