Workstation Laser Etching Machine

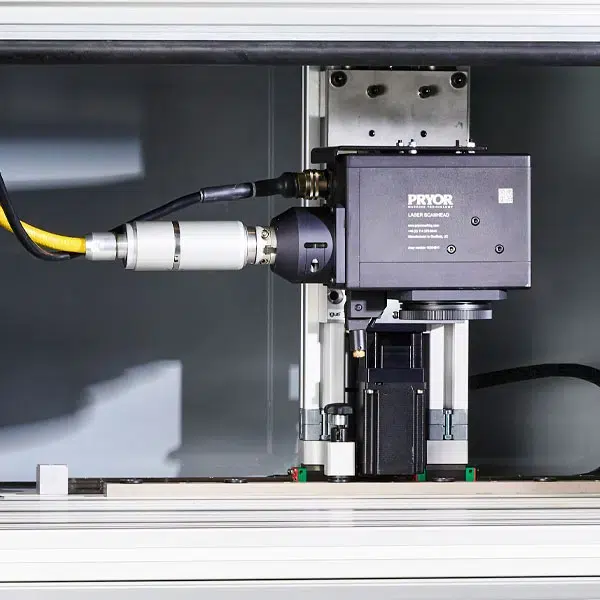

The Pryor Laser Workstation is a large, modular floor-standing laser engraving machine. The workstation is a Class 1 laser safe enclosure available in three sizes with manual or automated front access doors for component loading. Pryor offers two models of pulsed fibre laser, 20 watts, or 50 watts, to meet different marking requirements.

- Large and robust light-safe workstation

- Enclosure is quick and easy to access and operate

- Reliable, maintenance free with very low running costs

- Direct marking of large or multiple components

- Non-contact, fixtureless marking

- Permanent, high-contrast marking

- Fast, easy to use and versatile

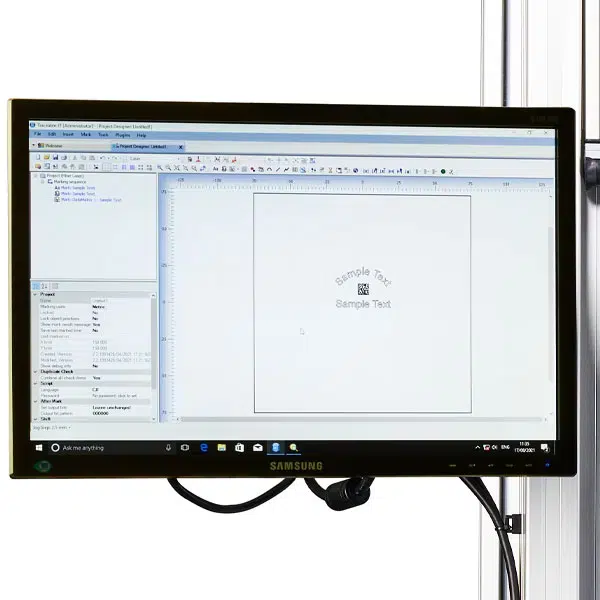

- Supplied with our windows-based Traceability Software

- Features

- Video

- Technical Data

Features

Laser Workstation

The Laser Workstation uses a fibre laser to engrave a permanent, high-contrast mark directly onto a component or label. Fibre laser technology is known for exceptional reliability, with diode life exceeding 50,000 hours, providing maintenance free marking and no consumable costs. Fibre lasers consume less than 200watts of power, making these lasers the most efficient on the market.

As a non-contact marking technology, components do not need to be clamped, ensuring set up and operation is fast and safe. Non-contact also means the marking process does not create stress points or deform the material.

The enclosure is modular, allowing the size of the cabinet to be scalable and has several possible upgrade additions for increased flexibility and functionality

Three standard Workstation sizes (width x depth)

o 1.0m x 0.5m

o 1.5m x 0.5m

o 2.0m x 0.5m

- Class 1 laser safe enclosure, completely interlocked for operator safety

- Floor standing machine, with an ergonomic working height

- 20W Fibre laser as standard, but higher power units available

- Pryor embedded laser controller

- Pryor laser scan-head mounted on a digital z axis with 400mm of z axis movement

- FT150 lens (100mm x 100mm marking area) as standard

- Integrated PC with mounted keyboard, mouse and monitor

- Traceability Software included

- Aluminium extruded, slotted base for easy location and mounting of fixtures and jigs

Video

Technical Data

Pryor Fibre Laser Specification

Pryor offers two models of pulsed fibre laser

YF20: 20W (Available in 3 vaieants, Eco, Standard and Pro)

YF50: 50W

Our 20W Laser has proven to be a reliable and high-quality solution for a variety of marking applications. It offers a wide frequency range (20kHz to 200kHz), capable of producing high contrast surface marking on a wide range of materials.

The laser is suited to high volume, high variety output and issupplied with a two-year product warranty on both the cabinet and integrated system.

Fibre Laser Features

- Exceptional reliability, Fit and forget performance with diode life exceeding 50,000 hrs

- Maintenance free marking with no consumable costs

- High quality marking on a wide range of materials including metals / alloys and plastics

- Low running costs, fibre lasers consume less than 200watts of power, making these lasers the most efficient on the market (1.06-micron wavelength)

- Wide operating temperatures between 0 and 42°C

- Industry leading Traceability Software

- Available in a range of class 1 enclosures

Also available as an integration package. The compact size and robust construction make the YF lasers the perfect solution for automated part marking tasks.

Intelligent laser controller can operate in a basic standalone mode or using the built-in USB connection it can connect to a PC for advanced operation using the Pryor Traceability software.

Visible ‘Pilot’ beam shows the marking location for fast, accurate setup.

Secondary (converging) ‘focus finder’ visible beam shows when the laser is focused.

Robust, easy to use control panel features high quality start/stop/focus finder push buttons with built in emergency stop and key-switch safety interlock control.

| Eco 20W | Standard 20W | 20W Pro | Standard 50W | |

| Pulse Energy | 0.7mJ | 1mJ | 1mJ | 1mJ |

| Average power | ~18.5W | 20W | 20W | 50W |

| Msquared | 1.3 | 1.6 | ||

| Polarisation | Random | |||

| Power Tunibility | 5% to 100% | |||

| Pulse Duration @ 20KHz | ~85ns | 100ns | 4,8,14,20,30,50,100 & 200ns | 120ns |

| Repetition Rate | 30 KHz to 60KHz | 20 KHz to 200KHz | 1.6 KHz to 1000 KHz | 50 KHz to 200 KHz |

| Long Term Power Stability | 1 – 3% | |||

| Operating Temperature | 0 to 42°C | |||

| Cooling | Active Air Cooling | |||

| Fibre Optic | 2.5m | 2 Meter Pigtail With 8mm Collimator/Isolator | ||

| Power | Less Than 200W – 110 or 220 VAC | |||

| Warranty | 1 year | 2 years as standard | ||